You often see safety shoes made from steel, aluminum, composite, leather, microfiber, textiles, rubber, polyurethane, and EVA. Manufacturers use steel, aluminum, or composite for toe caps; leather, microfiber, or textiles for uppers; rubber, polyurethane, or EVA for soles. Leather offers durability, rubber resists slips, and plastics help reduce weight. Choosing the right safety shoes material helps protect your feet, keeps you comfortable, and ensures your shoes last longer.

Choose safety shoes with the right toe cap material for your work environment. Steel offers maximum protection, while composite is lighter and non-metallic for metal detector areas.

Prioritize comfort by selecting shoes with cushioned insoles and flexible uppers. This helps reduce fatigue during long hours on your feet.

Look for breathable materials like mesh or moisture-wicking linings to keep your feet dry and cool, especially in hot work conditions.

You rely on the toe cap for protection against heavy impacts and compression. The most common safety shoes material for toe caps includes steel, aluminium, composite, and carbon. Each material meets strict safety standards, such as ASTM F2413-18 M I/75 C/75 EH, which means the toe cap can withstand an impact of 75 foot-pounds and a compressive load up to 2,500 pounds.

Here’s a quick comparison of the main toe cap materials:

|

Material Type |

Impact Resistance Rating |

Compressive Load Resistance |

Weight |

Temperature |

Metal Detector |

Profile Thickness |

Price |

Best For |

|---|---|---|---|---|---|---|---|---|

|

Steel |

I/75 |

2,500 pounds |

Heaviest |

Conducts |

Triggers |

Thinnest |

Lowest |

Heavy industry |

|

Aluminium |

I/75 |

2,500 pounds |

Middle |

Conducts |

Triggers |

Thin |

Middle |

General use, lighter weight |

|

Composite |

I/75 |

2,500 pounds |

Lightest |

Insulates |

Does NOT |

Thickest |

Highest |

Airports, cold, all-day wear |

|

Carbon |

I/75 |

2,500 pounds |

Lightest |

Insulates |

Does NOT |

Thin |

Highest |

High-tech, lightweight needs |

Tip: If you work in environments with metal detectors, composite or carbon toe caps help you avoid unnecessary alarms. For maximum protection in heavy industry, steel toe cap shoes remain the top choice.

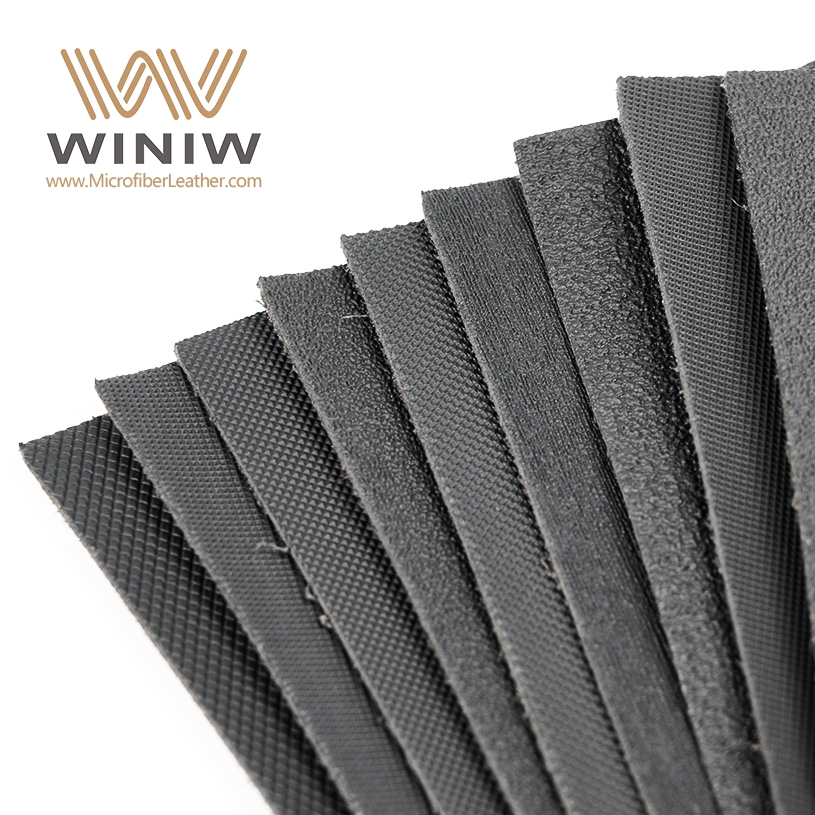

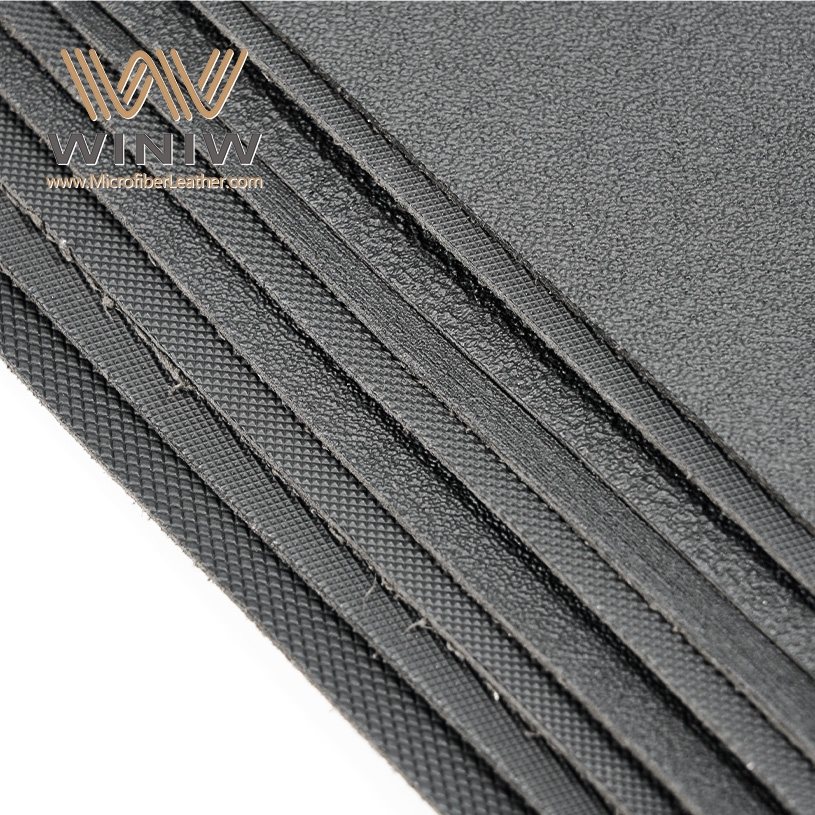

The upper part of your safety shoe secures your foot and shields it from external hazards. The most common safety shoes material for uppers includes leather, microfiber, and textile. Each material offers unique benefits for durability, flexibility, and comfort.

|

Material |

Abrasion Resistance |

Flexibility |

Water Resistance |

Breathability |

Notes |

|---|---|---|---|---|---|

|

Leather |

High |

Moderate |

Moderate |

Moderate |

Classic look, tough, needs maintenance |

|

Microfiber |

Very High |

High |

Low |

High |

Lightweight, easy to clean, vegan-friendly |

|

Textile |

Moderate |

Very High |

Low |

Excellent |

Breathable, lightweight, ideal for comfort |

You might choose leather for its toughness and classic appearance. Microfiber gives you a lightweight, flexible feel and is easy to clean. Textile uppers maximize breathability, making them ideal for hot environments or long hours on your feet.

The sole of your safety shoe keeps you steady and absorbs shock. Manufacturers use rubber, polyurethane (PU), and EVA (ethylene vinyl acetate) as the main safety shoes material for soles. Each material affects slip resistance, durability, and comfort.

Rubber soles provide excellent grip and outstanding chemical resistance. They last a long time and work well on slippery surfaces.

PU soles offer superior shock absorption and moderate durability. They feel lighter and more flexible than rubber.

EVA soles give you the best shock absorption and a soft, cushioned feel, but they wear out faster than rubber or PU.

|

Sole Material |

Shock Absorption |

Chemical Resistance |

Durability |

|---|---|---|---|

|

Rubber |

Good |

Excellent |

High |

|

PU |

Superior |

Good |

Moderate |

|

EVA |

Excellent |

Good |

Low |

Note: If you need slip resistance and durability, rubber soles are your best option. For lightweight comfort, PU and EVA are popular choices.

The lining inside your safety shoe manages moisture and boosts comfort. The most common safety shoes material for linings includes microfiber, polyester, nylon, and mesh. These materials wick away sweat, keep your feet dry, and help control odor.

|

Material |

Properties |

|---|---|

|

Microfiber |

Breathable, abrasion resistant, lightweight, wicks moisture |

|

Polyester |

Moisture-wicking, keeps feet dry, enhances comfort |

|

Nylon |

Lightweight, durable, can be treated with antibacterial solutions |

|

Mesh |

Offers breathability and ventilation, enhances moisture management |

Many modern linings use advanced technologies to keep your feet fresh and hygienic all day. Some linings provide continuous odor control, making your safety shoes more comfortable for long shifts.

Insoles support your arch and cushion your steps. The most common safety shoes material for insoles includes foam, gel, cork, and leather. Each material affects comfort, support, and fatigue reduction.

Foam insoles give you excellent support and help maintain proper foot alignment.

Gel insoles absorb shock and feel soft, which is great for standing or walking all day.

Cork insoles repel water and can combine with latex for extra comfort.

Leather insoles last a long time and provide both support and comfort.

You can also find specialized insoles, such as arch support, memory foam, orthotic, and heat-moldable types. These options help distribute weight evenly, reduce fatigue, and improve comfort during long wear.

Remember: Choosing the right insole material can make a big difference in how your feet feel after a long day at work.

You depend on safety shoes to shield your feet from workplace hazards. The right materials can prevent serious injury by offering impact resistance, compression resistance, and protection from sharp objects or electrical hazards. Steel, aluminum, and composite toe caps all meet strict standards for impact and compression. For example, these materials must withstand a 75-pound force and protect against a 2,500-pound compressive load. Some shoes include metatarsal guards to reduce the chance of injury to the top of your foot. Puncture-resistant soles use metal or non-metallic plates to stop sharp objects from penetrating. If you work around electricity, you need shoes with electric shock resistance. These shoes can insulate against voltages up to 18,000 volts for one minute without leaking current. Some safety shoes also offer static dissipative properties, which help prevent static buildup and reduce the risk of ignition in flammable environments.

If you work with heavy machinery, sharp tools, or electrical equipment, always check the safety ratings on your shoes. The right material can make the difference between a minor incident and a serious injury.

Key Protective Features in Safety Shoes:

|

Protective Feature |

Description |

|---|---|

|

Impact Resistance |

Withstands 75-pound force; maintains minimum interior height clearance |

|

Compression Resistance |

Withstands 2,500-pound force; same clearance as impact resistance |

|

Metatarsal Protection |

Reduces chance of injury to metatarsal bones |

|

Conductive Properties |

Reduces hazards from static electricity and ignition of chemicals |

|

Electric Shock Resistance |

Insulates against 18,000 volts at 60 Hz for 1 minute |

|

Static Dissipative |

Reduces hazards from low footwear resistance |

|

Puncture Resistance |

Protects against sharp objects penetrating the sole |

|

Chain Saw Cut Resistance |

Shields against chain saw cuts |

|

Dielectric Insulation |

Offers insulation against electrical hazards |

You spend long hours on your feet, so comfort matters as much as protection. Softer and more flexible materials, such as foam insoles and textile uppers, reduce pressure on your feet and help prevent fatigue. Studies show that shoes with stretchable fabric uppers and soft midsoles are the most comfortable. You may notice that soft suede or microfiber uppers feel better than stiff leather, especially if you walk or stand all day. Lightweight materials, like composite toe caps and EVA soles, also help reduce foot fatigue. Lower shoe weight means you can move more freely and stay comfortable during long shifts.

Shoes with lower pressure on the top of the foot feel more comfortable.

Stretchable fabrics and soft midsoles increase comfort.

Lightweight materials reduce fatigue and make movement easier.

Choose shoes with cushioned insoles and flexible uppers if you value all-day comfort.

You want your safety shoes to last, especially if you work in tough environments. Leather stands out for its superior durability and resistance to punctures and abrasions. It often outlasts synthetic materials, making it a smart investment for long-term use. Synthetic uppers, such as microfiber and textile, offer lightweight comfort but tend to wear down faster and may need more frequent replacement. For soles, rubber provides high durability and resists chemicals, while PU and EVA offer less durability but more comfort.

|

Material |

Durability |

Lifespan |

|---|---|---|

|

Leather |

Superior, resists punctures/abrasion |

Longer, outlasts synthetics |

|

Synthetic |

Less durable, wears faster |

Shorter, needs more replacements |

Leather withstands heavy use and conforms to your foot over time.

Synthetic materials are lighter and cheaper but may not last as long.

If you need shoes that can handle rough conditions, leather is your best choice for durability.

You need breathable shoes to keep your feet dry and healthy, especially in hot environments. Mesh and textile uppers allow air to flow, reducing sweat and helping your feet stay cool. Good airflow prevents moisture buildup, which lowers the risk of blisters and fungal infections. Leather also offers breathability and can be treated for waterproofing, making it versatile for different work conditions. Moisture-wicking linings, such as microfiber or polyester, pull sweat away from your skin and help prevent skin problems.

Mesh uppers enhance airflow and keep feet cool.

Moisture-wicking linings reduce sweat and lower the risk of blisters.

Leather balances breathability and durability.

For hot or humid workplaces, prioritize shoes with mesh or textile uppers and moisture-wicking linings.

You can use the table below to quickly compare the main benefits and trade-offs of common safety shoe materials:

|

Material Type |

Protection |

Comfort |

Durability |

Breathability |

Notes |

|---|---|---|---|---|---|

|

Steel Toe Cap |

Excellent (impact/compression) |

Heavy, less flexible |

Very durable |

Poor (conducts heat/cold) |

Triggers metal detectors |

|

Aluminum Toe Cap |

Good (impact/compression) |

Lighter than steel |

Less durable than steel |

Poor (conducts heat/cold) |

More expensive |

|

Composite Toe Cap |

Good (impact/compression) |

Lightweight, flexible |

May lose durability after impact |

Good (non-conductive) |

Does not trigger metal detectors |

|

Leather Upper |

Excellent (puncture/abrasion) |

Moderate |

Very durable |

Good |

Heavier, classic look |

|

Microfiber Upper |

Good |

High |

Moderate |

High |

Easy to clean, vegan-friendly |

|

Textile Upper |

Fair |

Very high |

Less durable |

Excellent |

Lightweight, best for hot climates |

|

Rubber Sole |

Excellent (slip/chemical) |

Good |

High |

Moderate |

Heavy, long-lasting |

|

PU Sole |

Good |

Superior |

Moderate |

Good |

Lightweight, flexible |

|

EVA Sole |

Fair |

Excellent |

Low |

Good |

Soft, wears out faster |

Use this table to match your work environment and personal needs with the right safety shoe material.

You find steel, composite, leather, and rubber as top safety shoe materials. Choose based on workplace hazards, comfort, and durability. For construction, steel toes protect against impact. In healthcare, slip-resistant soles help prevent falls. Always prioritize fit, certified protection, and long-lasting quality for the best results.

You find many types of safety shoes, such as steel toe, composite toe, water-resistant safety shoes, and chemical resistant splash shoes. Each type protects you from different workplace hazards.

You stay safer with water-resistant and anti-slip shoes. These safety shoes keep your feet dry and help you avoid the risk of slipping on wet or oily surfaces.

You benefit from leather and leather in safety shoes because they offer durability, comfort, and protection. These materials resist wear and help your safety shoes last longer.

Сканирование в wechat: