Вы сталкиваетесь с кожаными тканями в повседневной жизни. продукты , от обуви до курток. В качестве основного сырья для производства этих тканей используются шкуры животных, чаще всего коровьи. Кожа отличается уникальной текстурой, прочностью и гибкостью. Каждый год в мире перерабатывается огромное количество шкур животных для получения кожи.

В 2023 году объем производства сырых шкур в мире достиг около 21 миллиона тонн.

Прикоснувшись к натуральной коже, вы почувствуете её естественную текстуру и прочность. Процесс изготовления кожи из шкур животных включает несколько точных этапов. История кожевенного производства показывает, насколько важным это ремесло остаётся и сегодня.

Кожаные изделия изготавливаются из шкур животных, в основном коровьих, и подвергаются уникальному процессу, включающему дубление, окрашивание и отделку.

Натуральная кожа — это кожа высочайшего качества, сохраняющая свою естественную текстуру и долговечность, что делает ее идеальной для изделий класса люкс.

Устойчивое развитие становится все более растущей тенденцией в производстве кожи, причем растительное дубление является наиболее экологичным методом по сравнению с хромовым дублением.

Кожаные изделия известны своей прочностью и долговечностью, что делает их популярным выбором в индустрии моды, производства мебели и автомобилестроения.

Понимание различных видов кожи поможет вам выбрать правильный материал, соответствующий вашим потребностям, будь то товары премиум-класса или бюджетные варианты.

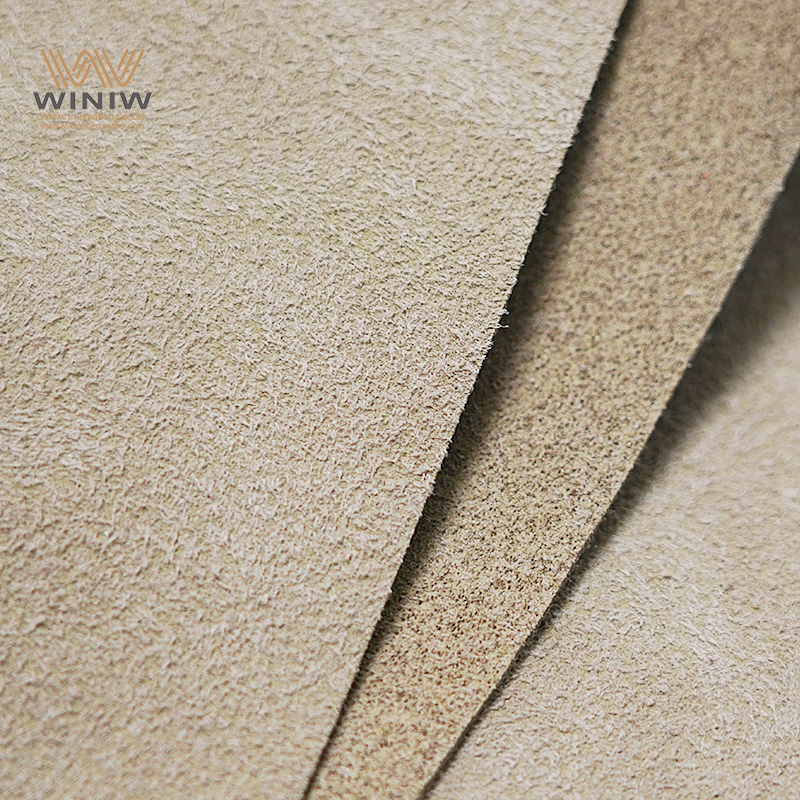

При изучении кожаных тканей вы обнаружите уникальную категорию материалов, которая отличается от традиционных тканей. Кожаная ткань Кожа производится из шкур животных, а не из пряденых или тканых волокон, таких как хлопок или полиэстер. Вы можете задаться вопросом: из чего делают кожу? Ответ прост: из шкур животных, в основном коров, коз, овец и свиней.

Кожаная ткань проходит особую обработку. Вы увидите такие этапы, как дубление, крашение и отделка. Эти этапы придают коже её фирменные качества. Вот что отличает кожаную ткань от других тканей:

Кожу получают из шкур животных, тогда как для производства большинства тканей используются растительные или синтетические волокна.

Процесс производства включает в себя дубление, крашение и отделку, которые не встречаются в других видах текстильного производства.

Кожаная ткань отличается прочностью, водостойкостью и теплоизоляцией. Эти характеристики отличают её от других материалов.

Кожаная ткань используется во многих изделиях. Вот некоторые из наиболее распространённых её видов:

Кожаные сумки

Кожаные кошельки

Кожаные куртки

Кожаная обувь

Мировой рынок кожаных тканей продолжает расти. Наблюдаются новые тенденции, такие как экологичное производство и многофункциональность. Молодые потребители теперь ищут бренды, ориентированные на устойчивое развитие и социальную ответственность.

Вы можете спросить, какие шкуры животных чаще всего используются в производстве кожевенных тканей. Ответ можно найти в таблице ниже:

|

Шкура животных |

Характеристики |

Распространенные применения |

|---|---|---|

|

коровья кожа |

Прочный, долговечный, универсальный |

Сумки, обувь, куртки, мебель |

|

Козел |

Мягче, легче |

Кошельки, перчатки, сумки, одежда |

|

Овца |

Гладкая, эластичная текстура |

Замша, куртки, мягкие аксессуары |

|

Свинья |

Прочный, дышащий |

Рабочие перчатки, обувь, подкладки |

Коровья кожа – ведущая отрасль, обеспечивая около двух третей всех кожевенных тканей в мире. Овцы, свиньи и козы также играют важную роль, но в меньших количествах. Вы заметите, что шкура каждого животного привносит в кожевенную ткань свои уникальные качества, делая её пригодной для различных изделий. Выбирая кожевенную ткань, вы выбираете материал, созданный природой и усовершенствованный благодаря искусным методам обработки.

Вам наверняка интересно, как производят кожу и какие этапы превращают шкуры животных в прочный кожаный материал. Этот процесс включает три основных этапа: подготовку к дублению, дубление и последующее дубление и отделку. Каждый этап играет решающую роль в формировании окончательных качеств кожевенной ткани.

Когда вы спрашиваете, из чего делают кожу, вы обнаружите, что отправной точкой являются шкуры животных. Перед дублением кожи необходимо подготовить её, чтобы обеспечить качество и долговечность. Этап подготовки включает в себя несколько этапов:

Отверждение : Шкуры обрабатываются солью для предотвращения гниения. Сухое или мокрое посоливание помогает сохранить материал.

Замачивание : Шкуры замачиваются в чистой воде, чтобы удалить соль и восстановить влажность.

Известкование : Шкуры обрабатываются известью для удаления волос и нежелательных тканей.

Обезволашивание, отпаривание и мездрение : Вы удаляете посторонние салфетки, чтобы очистить поверхность.

Обеззоливание : Вы нейтрализуете известь, чтобы подготовить ее к дальнейшей обработке.

Батинг или Пьюринг : Для размягчения шкур используются ферменты.

Промачивание : Шкуры замачиваются в растворе, чтобы подготовить их к травлению.

Маринование : Шкуры обрабатываются кислотой и солью, чтобы подготовить их к дублению.

При подготовке кожи к дублению используются различные химикаты и вещества. Растительное дубление основано на экстрактах древесины и орехов деревьев и кустарников. Хромовое дубление использует соли хрома, а бесхромовые методы – глутаральдегид. В некоторых процессах используются цеолиты, которые поглощают или выделяют воду.

Совет: правильная подготовка к дублению гарантирует, что кожаная ткань останется прочной и гибкой на протяжении всего срока службы.

Переходим к процессу дубления, который стабилизирует белковую структуру кожи и предотвращает её разложение. Этот этап имеет решающее значение в истории кожевенного производства и определяет современный подход к её производству. Существует несколько методов дубления, каждый из которых обладает уникальными характеристиками:

|

Метод дубления |

Описание |

Распространенность в промышленности |

|---|---|---|

|

Растительное дубление |

Использует растительные экстракты; экологически безопасен; производит прочную, долговечную кожу. |

~10-12% |

|

Хромовое дубление |

Использует соли хрома; быстро и эффективно; делает кожу мягкой и эластичной. |

~85% |

|

Масляный загар |

Использует масла и жиры; производит мягкую, водостойкую кожу. |

Менее распространено |

|

Дубление квасцами |

Использует соли алюминия; производит светлую, прочную кожу. |

Специальные приложения |

|

Загар мозга |

Традиционный метод с использованием мозгов животных; позволяет получить мягкую, податливую кожу. |

Обычно не практикуется |

Хромовое дубление обеспечивает почти 80% мирового производства кожи. Растительное дубление составляет около 10–12% производства. Как видите, хромовое дубление — быстрый и эффективный процесс, но он приводит к образованию токсичных сточных вод и оставляет после себя вредные вещества, такие как хром и мышьяк. Растительное дубление использует натуральные танины из возобновляемых источников, что позволяет получать биоразлагаемые сточные воды и избегать синтетических отходов. Этот метод считается единственным по-настоящему… устойчивый вариант по сравнению с синтетическими альтернативами.

Примечание: Кожевенные изделия часто изготавливаются из шкур животных, являющихся побочными продуктами мясной и молочной промышленности. Производство кожи обеспечивает до 26% прибыли крупных скотобоен. Однако дубление 1 кг кожи требует до 2,5 кг химикатов и 250 литров воды, что приводит к образованию до 6,1 кг твёрдых отходов.

После дубления наступает этап постдубления и финишной обработки. Этот этап придаёт кожевенной ткани окончательный вид, текстуру и эксплуатационные характеристики. Выполняется механическая обработка кожи для придания ей формы и разглаживания, а также химическая обработка для окрашивания, смазки, смягчения и нанесения финишных покрытий.

Выполняется последовательная обработка, такая как додубливание, окрашивание и жирование. Окрашивание обычно производится партиями, а жирование повышает прочность и гибкость. Кожа растительного дубления проходит этапы отверждения, прокатки и полировки. Отделка хромированной кожи часто включает нанесение защитного слоя.

Методы отделки влияют как на долговечность, так и на внешний вид. В таблице ниже показано, как различные методы обработки меняют характеристики кожаных изделий:

|

Техника отделки |

Описание |

Характеристики |

|---|---|---|

|

Защитные покрытия |

Применяется для защиты кожи от воды, пятен и износа. |

Повышает водостойкость и долговечность, продлевая срок службы кожи. |

|

Глянцевая отделка |

Использует материалы, усиливающие блеск, для придания блестящего внешнего вида. |

Повышает визуальную привлекательность и обеспечивает защиту поверхности от пятен и грязи. |

|

Матовая отделка |

В результате получается неотражающий, естественный вид. |

Позволяет увидеть естественную текстуру, что придает изделиям аутентичность, но они более подвержены образованию пятен. |

|

Антикварная отделка |

Придает коже винтажный вид с помощью более темных красителей. |

Улучшает текстуру и добавляет глубину, создавая состаренный вид. |

|

Текстурирование |

Создает узоры и текстуры для визуального интереса. |

Изготавливается методом тиснения или конгревного тиснения, часто используется для уникальных, высококачественных изделий. |

Вы заметите, что отделка не только улучшает внешний вид кожаной ткани, но и повышает её устойчивость к воде, пятнам и износу. Благодаря этим процессам кожаная ткань подходит для широкого спектра изделий.

Предупреждение об устойчивом развитии: процесс дубления кожи часто включает использование токсичных химикатов, представляющих опасность для здоровья человека и окружающей среды. Производство одной сумки из коровьей кожи требует около 17 128 литров воды и влечет за собой выбросы 100,5 кг CO2-эквивалента по сравнению с 14,4 кг для синтетической сумки. Производство кожаных тканей по-прежнему ресурсоемко, но растительное дубление предлагает более экологичную альтернативу.

Теперь вы знаете, как производится кожа: от обработки шкур животных до готовых изделий из кожи. Каждый этап определяет прочность, внешний вид и экологичность кожаной ткани.

Изучив основные виды кожи, вы обнаружите, что каждый из них обладает уникальными качествами и сферами применения. Понимание различий между натуральной кожей, высококачественной кожей и спилком или склеенной кожей поможет вам выбрать правильную кожевенную ткань, соответствующую вашим потребностям.

Натуральная кожа считается самой высококачественной из доступных на рынке. Этот тип кожи характеризуется нетронутым внешним слоем шкур животных. Поверхность сохраняет свою естественную текстуру и неровности, что придаёт ей уникальный внешний вид и тактильные ощущения. Эта кожа прочная и долговечная, что делает её идеальной для изделий, подвергающихся интенсивному использованию. Обратите внимание, что со временем на натуральной коже образуется насыщенный налёт, который придаёт ей особый шарм. Сохраняя натуральные волокна, эта кожаная ткань остаётся дышащей и прочной. Высококачественные сумки, обувь, ремни и мебель часто используют натуральной кожи благодаря её исключительной прочности и природной красоте.

Совет: Если вам нужна высококачественная кожа, которая прослужит долгие годы, лучшим выбором будет натуральной кожи.

Кожа с верхним слоем (top grain leather) — ещё один популярный вид кожи. Этот вид кожи получается, когда дубильщик шлифует поверхность, удаляя изъяны. Этот процесс создаёт более гладкую текстуру, делая кожу более мягкой и эластичной. Хотя кожа с верхним слоем (top grain leather) по-прежнему остаётся высококачественной, она немного менее прочная и менее воздухопроницаемая, чем кожа с верхним слоем. Вы заметите, что она не так сильно покрывается патиной, но её легче чистить и ухаживать. Кожа с верхним слоем используется во многих изделиях, включая сумки, кошельки, ремни, обувь, мебель и одежду. Этот тип кожи сочетает в себе качество и доступность, что делает её распространённым выбором в текстильной промышленности.

|

Атрибут |

Кожа высшего качества |

Натуральная кожа |

|---|---|---|

|

Появление |

Гладкая, дефекты отшлифованы |

Видимые зерна и дефекты |

|

Долговечность |

Износостойкий, менее долговечный, чем цельное зерно |

Самая прочная кожа на рынке |

|

Воздухопроницаемость |

Менее воздухопроницаемый |

Более дышащий |

|

Патина |

Меньше патины |

Образует богатую патину |

|

Чувствовать |

Мягкий, гибкий |

Твердый, размягчается при использовании |

|

Обслуживание |

Легко чистить |

Нуждается в кондиционировании |

|

Цена |

Более доступный |

Дорогой |

|

Распространенные применения |

Сумки, кошельки, мебель, автокресла |

Высококачественные сумки, обувь, ремни, мебель |

Существуют также виды кожевенной ткани, изготовленные из нижних слоёв шкур животных. Спилок получают из этих внутренних слоёв, что делает его менее прочным и низкокачественным, чем цельнозерновая или лицевая кожа. Производители часто используют спилок в изделиях, не требующих высокой прочности. Для производства склеенной кожи используются обрезки измельчённой кожи, смешанные с латексом или полиуретаном, которые затем прессуются на сетке из волокон. Качество склеенной кожи зависит от количества использованной натуральной кожи, которое может варьироваться от 10% до 90%. Склеенную кожу часто можно увидеть в недорогой мебели и аксессуарах.

|

Особенность |

Спилок кожи |

Склеенная кожа |

|---|---|---|

|

Состав |

Нижние слои шкуры |

Измельченная кожа с латексом/полиуретаном |

|

Качество |

Ниже верхнего зерна или полного зерна |

Зависит от процентного содержания кожаных волокон |

|

Приложения |

Различные товары, не для элитной продукции |

Недорогая мебель, аксессуары |

На вопрос, из чего делают кожу, вы увидите, что ответ зависит от типа кожи и слоя используемой шкуры. Понимая основные виды кожи, вы сможете выбрать подходящую для своего проекта, независимо от того, нужна ли вам высококачественная кожа для предметов роскоши или более доступные варианты для повседневного использования.

Выбирая кожаные изделия, вы рассчитываете на их долговечность. Кожа отличается впечатляющей прочностью и долговечностью. Вы можете носить кожаную куртку или сумку долгие годы, не подвергая их износу. Натуральная кожа устойчива к разрывам и растяжениям лучше большинства синтетических материалов. Это делает её лучшим выбором для изделий, предназначенных для ежедневного использования.

Вы можете задаться вопросом, как кожа соотносится с синтетические альтернативы . Таблица ниже показывает различия:

|

Материал |

Долговечность |

Сила |

|---|---|---|

|

Натуральная кожа |

Долговечный, может прослужить десятилетия |

Более устойчивый, выдерживает износ |

|

Синтетическая кожа |

Как правило, менее долговечны, могут трескаться |

Часто слабеет, может отслаиваться или терять блеск |

Как видите, изделия из натуральной кожи выдерживают суровые условия. Синтетическая кожа часто трескается или отслаивается при частом использовании. Веганская кожа Несмотря на свою прочность, кожа обычно уступает натуральной. Многие виды кожи, например, телячья, обладают высокой прочностью на разрыв. Некоторые кожаные изделия сочетают телячью кожу с трикотажной или овечьей подкладкой для дополнительной поддержки.

Совет: если вы хотите, чтобы изделия прослужили долго, выбирайте изделия из натуральной кожи.

Кожаные ткани используются во многих отраслях промышленности благодаря своей прочности и стильному дизайну. Изделия из кожи используются в моде, производстве мебели, автомобилей и спорта. В таблице ниже представлены наиболее распространённые области применения:

|

Промышленность |

Приложения |

|---|---|

|

Мода |

Одежда (брюки, юбки, куртки), обувь (туфли, сапоги), аксессуары (сумки, ремни, кошельки) |

|

Обивка |

Мебель (стулья, диваны, пуфы), автомобильная обивка (автомобильные сиденья, дверные панели) |

|

Аксессуары |

Брелки, украшения, ремешки для часов, чехлы для телефонов, чехлы для ноутбуков |

|

Сумки |

Прочные сумки, рюкзаки, портфели, дорожные сумки |

|

Дом Декор |

Декоративные подушки, коврики, настенные покрытия, абажуры |

|

Спортивные товары |

Спортивный инвентарь (перчатки, бейсбольные и футбольные мячи, боксерская экипировка) |

Изделия из кожи можно увидеть повсюду. В автомобильной промышленности кожа используется для сидений, рулей и приборных панелей, особенно в автомобилях класса люкс. Производители мебели используют кожу для обивки диванов и кресел-реклайнеров, придавая домам элегантность и комфорт. Изделия из кожи, такие как ремни, кошельки и сумки, остаются популярными благодаря своему классическому виду и долговечности.

Примечание: кожаные ткани адаптируются к новым тенденциям, включая экологичное производство и современный дизайн, что делает их разумным выбором для многих целей.

Теперь вы знаете, что кожаные изделия изготавливаются из шкур животных и проходят множество этапов, прежде чем попасть к вам. Процесс включает в себя консервацию, замачивание, золение, удаление волос, мездрение, расщепление и дубление, как показано ниже:

Сохранение

Замачивание

Известкование

Удаление волос

Мясистость

Разделение

Загар

Различные виды кожи обладают уникальными качествами и возможностями применения:

|

Тип |

Ключевые особенности |

Распространенные применения |

|---|---|---|

|

Цельнозерновой |

Натуральная текстура, дышащая |

Предметы роскоши, мебель |

|

Top-Grain |

Гладкий, однородный, менее воздухопроницаемый |

Сумки, мебель среднего ценового диапазона |

|

Расколоть |

Пигментированный, менее стойкий |

Зоны мебели, не требующие прикосновений |

|

Связанный |

Не дышащий, бюджетный |

Краткосрочная мебель |

Кожу можно увидеть в моде, автомобилях и дизайне интерьера. Кожаные ткани остаются важными, поскольку сочетают в себе прочность, комфорт и неподвластный времени стиль во многих отраслях.

Протирайте поверхность мягкой влажной тканью. Избегайте использования агрессивных химикатов и замачивания кожи. Для удаления стойких пятен используйте чистящее средство, предназначенное для кожи. Всегда сначала проверяйте средство на небольшом участке.

Кожаные изделия часто изготавливаются из шкур животных, являющихся побочными продуктами мясной промышленности. Растительное дубление использует растительные материалы и снижает уровень загрязнения окружающей среды. Хромовое дубление быстрее, но производит больше отходов. Выбирайте кожу растительного дубления, чтобы быть более экологичным вариантом.

Вы можете оценить текстуру и запах. Натуральная кожа тёплая на ощупь и имеет естественную текстуру. Синтетическая кожа часто выглядит однородным и пахнет пластиком. Вы также можете обратить внимание на этикетки или спросить продавца.

Совет: Согните материал. На натуральной коже видны морщины и складки, а синтетическая кожа остаётся гладкой.

Кожаные изделия можно найти в обуви, куртках, сумках, ремнях, мебели и автомобильных сиденьях. Спортивный инвентарь, такой как перчатки и мячи, также изготавливается из кожи. Многие бренды используют кожу из-за её долговечности и классического стиля.

Кожу необходимо регулярно чистить и кондиционировать. Берегите её от прямых солнечных лучей и влаги. Раз в несколько месяцев используйте кондиционер для кожи, чтобы она оставалась мягкой и не трескалась.

Сканирование в wechat: